图解车工/数控车工快速入门

图解车工/数控车工快速入门基本信息

| 书 名 | 图解车工/数控车工快速入门 | 作 者 | [美]皮特·霍夫曼(Peter、Hoffman)、[美]埃里克·霍普韦尔(Eric、Hopewell) |

|---|---|---|---|

| ISBN | 9787111612681 | 定 价 | 59.8元 |

| 出版社 | 机械工业出版社 | 出版时间 | 2019年4月 |

| 装 帧 | 平装 | 开 本 | 16开 |

出版说明

序

第

1章 车床概述 ···························· 1

1.1 概述 ·············································· 2

1.2 主轴箱 ··········································· 2

1.2.1 主轴 ········································ 2

1.2.2 变速箱

····································· 5

1.3 床身 ·············································· 5

1.4 溜板 ·············································· 5

1.4.1 床鞍 ········································ 5

1.4.2 丝杠和光杠

······························· 7

1.4.3 溜板箱

····································· 7

1.5 尾座 ·············································· 8

1.6 车床规格 ········································ 8

1.6.1 回转直径 ·································· 8

1.6.2 床身长度 ·································· 9

第

2章 车床上的工件夹紧和刀具

夹紧设备 ··························· 10

2.1 概述············································· 11

2.2 工件夹紧······································· 11

2.2.1 卡盘 ······································· 11

2.2.2 夹头 ·······································15

2.2.3 花盘 ·······································18

2.2.4 工件在两个顶尖之间夹紧·············18

2.2.5 心轴 ·······································22

2.2.6 工件的辅助支承方法···················23

2.3 刀具夹紧·······································25

2.3.1 摆杆式刀具夹紧·························25

2.3.2 快换式刀具夹紧·························26

2.3.3 可转位刀架

······························27

2.3.4 孔加工刀具夹紧·························28

第

3章 车床操作 ··························· 29

3.1 概述·············································30

3.2 背吃刀量、切削速度、进给量和加工工时

的计算·········································· 30

3.2.1 背吃刀量 ································· 30

3.2.2 切削速度 ································· 31

3.2.3 进给量

···································· 31

3.2.4 粗加工与精加工························· 31

3.2.5 加工工时的计算························· 32

3.3 通用车床操作安全事项 ····················· 32

3.4 端面车削和外圆车削 ························ 33

3.4.1 端面车削和外圆车削刀具············· 33

3.4.2 刀具的基本几何参数··················· 35

3.4.3 端面车削 ································· 41

3.4.4 外圆车削 ································· 46

3.4.5 轴肩车削 ································· 49

3.5 锉削与抛光 ···································· 54

3.6 中心孔钻与定点钻 ··························· 56

3.6.1 中心孔钻 ································· 56

3.6.2 定点钻

···································· 56

3.7 车床上的孔加工 ······························ 57

3.7.1 钻孔 ······································· 57

3.7.2 铰孔 ······································· 58

3.7.3 加工沉头孔和埋头孔··················· 58

3.7.4 镗孔 ······································· 58

3.7.5 加工内轴肩

······························ 60

3.8 使用丝锥和板牙加工螺纹 ·················· 61

3.9 成形加工 ······································· 61

3.10 切槽和切断 ·································· 62

3.11 滚花 ··········································· 64

第

4章 手动车螺纹 ························ 67

4.1 概述············································· 68

4.2 螺纹术语 ······································· 68

4.3 配合等级 ······································· 69

4.4 确定螺纹数据 ································· 70

4.4.1 外螺纹的螺纹大径······················ 70

#12;

4.4.2 内螺纹的螺纹小径······················ 70

4.4.3 刀架进给量

······························ 70

4.4.4 螺纹中径 ································· 72

4.5 在车床上加工螺纹 ··························· 72

4.6 车床的调整 ···································· 73

4.6.1 安装工件 ································· 73

4.6.2 调整进给箱

······························ 73

4.6.3 调整小滑板

······························ 74

4.6.4 调整主轴转速···························· 75

4.6.5 安装、调整刀具························· 75

4.7 车螺纹操作 ···································· 76

4.7.1 设置刀具的参考位置··················· 76

4.7.2 乱扣盘和开合螺母······················ 76

4.7.3 螺纹车刀的进刀与调位················ 77

4.7.4 螺纹收尾法

······························ 78

4.8 螺纹测量 ······································· 80

4.8.1 螺纹环规与塞规························· 80

4.8.2 螺纹千分尺

······························ 80

4.8.3 三线法

···································· 81

4.8.4 牙型测量 ································· 82

4.9 其他牙型 ······································· 82

4.9.1 梯形螺纹 ································· 82

4.9.2 圆锥管螺纹

······························ 82

4.9.3 锯齿形螺纹

······························ 83

第

5章 锥面车削 ··························· 84

5.1 概述············································· 85

5.2 典型锥面的尺寸标注法 ····················· 85

5.2.1 角度标注法

······························ 85

5.2.2 变化率标注法···························· 85

5.3 锥面尺寸和计算 ······························ 86

5.3.1 将

TPI或

TPF转化为角度尺寸 ······ 89

5.3.2 将角度尺寸转化为

TPI或

TPF ······· 89

5.4 锥面车削方法 ································· 90

5.4.1 宽刃切削法

······························ 90

5.4.2 转动小滑板法····························90

5.4.3 锥面靠模法

······························92

5.4.4 尾座偏移法

······························94

第

6章 数控加工基础 ····················· 97

6.1 概述·············································98

6.2 数控机床控制单元 ···························99

6.3 数控运动控制 ······························· 100

6.3.1 传动丝杠 ······························· 100

6.3.2 数控导轨 ······························· 100

6.3.3 伺服电动机

···························· 101

6.4 坐标系 ········································ 101

6.4.1 笛卡儿坐标系·························· 102

6.4.2 极坐标系 ······························· 103

6.5 定位系统 ····································· 103

6.5.1 绝对定位系统·························· 103

6.5.2 增量定位系统·························· 104

6.6 代码 ··········································· 104

6.6.1 G代码 ·································· 104

6.6.2 M代码 ·································· 105

6.6.3 其他字地址指令······················· 105

6.6.4 二进制代码

···························· 107

6.7 对话型编程 ·································· 107

6.8 数控程序的组成 ···························· 107

6.8.1 安全启动 ······························· 108

6.8.2 材料去除 ······························· 108

6.8.3 程序结尾 ······························· 109

第

7章 数控车削概述 ····················110

7.1 概述 ············································111

7.2 车床的类型 ·································· 113

7.2.1 转塔车床 ······························· 113

7.2.2 组合刀具车床·························· 113

7.2.3 数控车床 ······························· 114

7.2.4 瑞士车削中心·························· 114

#12;

7.3 刀具安装 ····································· 116

7.4 工件夹持 ····································· 121

7.4.1 工件夹持夹头·························· 121

7.4.2 工件夹持卡盘·························· 122

7.5 工艺策划 ····································· 122

第

8章 数控车削编程 ··················· 123

8.1 概述 ··········································· 124

8.2 车削的坐标定位 ···························· 124

8.3 车削运动的类型 ···························· 124

8.3.1 车削的快速移位——G0 ············· 124

8.3.2 车削的线性插补——G1 ············· 124

8.3.3 车削的圆弧插补——G2和

G3 ····· 125

8.4 无轴运动指令 ······························· 128

8.4.1 切削的主轴速度······················· 128

8.4.2 换刀指令 ······························· 129

8.4.3 顺序号

·································· 129

8.4.4 程序停止指令·························· 129

8.4.5 安全启动、主轴启动和

换刀

/刀具偏置指令的总结 ········ 129

8.5 加工操作 ····································· 130

8.5.1 冷却剂

M代码 ························ 130

8.5.2 端面车削 ······························· 130

8.5.3 钻孔操作 ······························· 130

8.5.4 直线车削 ······························· 131

8.5.5 带锥度车削

···························· 134

8.5.6 仿形车削 ······························· 134

8.5.7 粗加工

·································· 134

8.5.8 精加工

·································· 136

8.6 固定循环 ····································· 136

8.6.1 孔加工固定循环······················· 136

8.6.2 攻螺纹固定循环······················· 138

8.6.3 粗车和精车固定循环 ················· 140

8.6.4 车螺纹固定循环······················· 140

8.6.5 刀尖半径补偿·························· 143

第 9章 数控车削的设置与操作 ········ 148

9.1 机床控制面板 ······························· 149

9.2 工件夹紧设置 ······························· 150

9.3 机床坐标系和工件坐标系 ················ 153

9.4 工件偏移设置 ······························· 153

9.5 车削的切削刀具 ···························· 155

9.5.1 切削刀具的安装······················· 155

9.5.2 车削的切削刀具偏位 ················· 155

9.6 车削的程序入口 ···························· 158

9.7 车床的操作 ·································· 158

9.7.1 程序验证 ······························· 158

9.7.2 自动模式 ······························· 159

图解车工/数控车工快速入门造价信息

本书采用通俗易懂的语言,介绍了车削加工和数控车削加工所需掌握的基本知识和技能。本书主要内容包括:车床概述、车床上工件夹紧和刀具夹紧设备、车床操作、手动车螺纹、锥面车削、数控加工基础、数控车削简介、数控车削编程、数控车削的设置与操作。

图解车工/数控车工快速入门常见问题

-

要想知道数控车工是干什么的首先你要了解什么是数控车床!在此介绍一下数控车床:数控机床是数字控制机床的简称,是一种装有程序控制系统的自动化机床。该控制系统能够逻辑地处理具有控制编码或其他符号指令规定的程...

-

数控车工是运用数控车床进行机械加工的工作。一、数控机床是数字控制机床的简称,是一种装有程序控制系统的自动化机床。该控制系统能够逻辑地处理具有控制编码或其他符号指令规定的程序,并将其译码,从而使机床动作...

-

1.天车工须经训练考试,并持有操作证者方能独立操作,未经专门训练和考试不得单独操作。2.开车前应认真检查设备机械、电气部分和防护保险装置是否完好、可靠。如果控制器制动器、限位器、电铃、紧急开关等主要附...

图解车工/数控车工快速入门文献

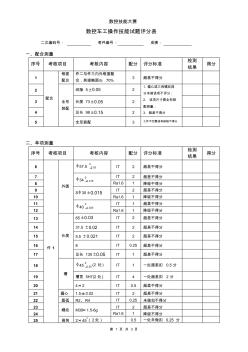

数控车工评分表

数控车工评分表

数控技能大赛 数控车工操作技能试题评分表 二次编码号: 考件编号 : 成绩: 第 1 页 共 3 页 一、配合测量 序号 考核项目 考核内容 配分 评分标准 检测 结果 得分 1 配合 锥面 配合 件二与件三内外锥面配 合,其接触面≥ 70% 3 超差不得分 2 全形 装配 间隙 5 05.0 2 1. 偏心或三角螺纹部 分未做该项不评分; 2. 该项尺寸需全形装 配测量; 3. 超差不得分 3 长度 73 05.0 2 4 总长 98 15.0 2 5 全形装配 3 工件不完整或有缺陷不得分 二、单项测量 序号 考核项目 考核内容 配分 评分标准 检测 结果 得分 6 件 1 外圆 57.5 0 03.0 IT 2 超差不得分 7 34 0 016.0 IT 2 超差不得分 8 Ra1.6 1 降级不得分 9 S 30 015.0 IT 2 超

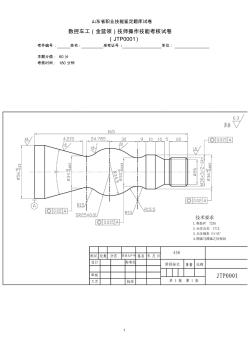

数控车工(技师)-技能试题

数控车工(技师)-技能试题

山东省职业技能鉴定题库试卷 数控车工(金蓝领)技师操作技能考核试卷 (JTP0001) 考件编号 : 姓名 : 准考证号 : 单位: 1 本题分值: 60分 考核时间: 180 分钟 山东省职业技能鉴定题库试卷 数控车工(金蓝领)技师操作技能考核试卷 (JTP0001) 考件编号 : 姓名 : 准考证号 : 单位: 2 考核要求: (1)根据现场机床的实际情况和工艺方案,手工操作加工出定位面 (2)根据现场机床的实际情况,修改模拟数控加工程序,然后进行实际加工。 (3)工件坯料有严重不符合图样要求或在切削过程中发现材料有严重缺陷的情况 , 由 现场裁判组裁决。 (4)除指定的刃具、工具、量具之外 , 不得使用其它工具。 (5)车刀使用硬质合金可转位车刀。 ( 6)未有说明的问题由现场裁判组裁决。

《图解叉车工快速入门》由赵之璋编著,《图解叉车工快速入门》以简洁、通俗的语言阐述了叉车工应掌握的必备知识。其主要内容有:叉车的基本知识,叉车的行驶装置、动力装置、电气装置、液压装置,叉车的驾驶与操作,叉车的运行材料及叉车的维护与保养。

本书采用全程图解的方式,主要介绍了数控车床基础知识,数控车削加工工艺,数控车床操作、维护、保养及故障诊断等知识,同时通过大量实例重点介绍了数控车床的编程以及数控车床典型零件的加工。

《图解数控车工基本操作技能》以SIEMENS 802D系统数控车床为例,以图解的形式深入浅出地阐述了数控车床的操作技能和编程应用,主要包括数控车床入门基础、数控车床编程、数控车床的操作、数控加工实例等内容。《图解数控车工基本操作技能》从基础开始,每一知识点的介绍均以任务目标的形式体现。

《图解数控车工基本操作技能》内容具体,图解丰富、详细,实用性非常强。《图解数控车工基本操作技能》可供青工自学和上岗、转岗再就业人员培训使用。

- 相关百科

- 相关知识

- 相关专栏

- 图解钣金工入门·考证一本通

- 图解钣金工入门与提高

- 图解钣金工快速入门

- 图说冲压模具设计要点与技巧

- 图说配电网工程作业风险点管控

- 图说香港历史建筑1841-1896

- 图说香港历史建筑1897-1919

- 图说香港历史建筑1920-1945

- 图诺德恩梯基车辆检测技术服务(上海)有限公司

- 圆刀杆夹尺寸

- 圆钢管活性粉末混凝土柱静动力性能与设计方法

- 圆锥叶轮木

- 圆锥滚子超精机第3部分:精度检验

- 圆锥滚子超精机系列型谱

- 圆锥滚子轴承套圈磨超机床

- 圆锥铰刀

- 怡达快速电梯SCORE项目获国际劳工组织高度评价

- 在LaTeX中使用TikZ画图的入门例子V1.5

- 在数控机床上通过监视主轴电机负荷实时监控刀具寿命

- 多功能快速连接法兰CN209743850U

- 中国阳江(五金刀剪)知识产权快速维权中心正式运行

- 早期抑制快速响应(ESFR)喷淋系统安装技术

- 感应加热快速处理全螺纹钢筋研制与力学性能分析

- 广东某建筑施工企业在快速成长期薪酬设计策略

- 工频零点电流转移限流及405kV快速真空开关仿真

- 关于对城市轨道交通优化实施快速、有效安检基础方案

- 关于快速公交专用道BRT规划设计方法

- 华为施工工艺室内给水排水管道节点图做法大全节点图解

- 基于CAN总线数控系统远程输入输出模块设计与实现

- 工艺工法公路隧道紧急停车带二次衬砌快速施工工法

- 基于MapInfo洞室施工地质快速编录系统研制

- 国务院办公厅关于加强城市快速轨道交通建设管理通知